DCPS > Forklift Batteries & Industrial Batteries > How Forklift Batteries Work

Forklift Batteries

- How Forklift Batteries Work

-

They're Powered by Science & Chemistry!

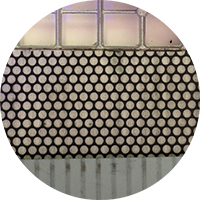

Have you ever wondered about what makes your forklift batteries tick? Take a behind-the-scenes look at the chemistry and science that make forklift batteries work. Successful battery function comes from several things coming together to work, but we'll start with the lead coated plates. These plates are rectangular shaped and have been alloyed with a little bit of antimony. Lead plates are basically a grid with rectangular holes that allows the lead to form thin walls by permeating the holes. The holes are filled with a mixture of Lead Oxide and diluted sulfuric acid that is pressed into the holes on both sides of the plate (which increases the surface area drastically). The lead and acid paste mixture stays porous once dry, which allows the acid to react with the lead in the plate.

Have you ever wondered about what makes your forklift batteries tick? Take a behind-the-scenes look at the chemistry and science that make forklift batteries work. Successful battery function comes from several things coming together to work, but we'll start with the lead coated plates. These plates are rectangular shaped and have been alloyed with a little bit of antimony. Lead plates are basically a grid with rectangular holes that allows the lead to form thin walls by permeating the holes. The holes are filled with a mixture of Lead Oxide and diluted sulfuric acid that is pressed into the holes on both sides of the plate (which increases the surface area drastically). The lead and acid paste mixture stays porous once dry, which allows the acid to react with the lead in the plate.

Once the lead plates are dry, they are stacked together using separators, placed into a plastic jar (known as battery cells), and placed into the battery container. In each cell there is always one more negatively charged plate than positively charged plate. The plates are connected so they are stacked together with every other plate being negative and positive. After the sulfuric acid and water mixture (electrolyte) has been added to the cell, it’s given the first forming charge. Positive plates slowly turn a chocolatey brown color due to lead dioxide. Negative plates turn a slate gray color which is generally known as 'spongy' lead. When the battery has been assembled, it’s basic function depends on negative and positive electrodes. These electrodes must be made of unlike materials. If they aren’t, the cell won’t be able to conduct an electric current. Negative electrodes provide electrons to the external circuit, which is sometimes known as load, during discharge. Positive electrodes receive electrons from the external circuit during discharge. In a fully charged forklift battery, the negative electrode is made of sponge lead, while the positive electrode is made up of lead dioxide. In order to keep the positive and negative electrodes isolated, a separator needs to be used. Separators can be made using different materials, generally plastic or glass that is permeable. It’s important to keep the electrodes apart because if they come into contact, the cell will short-circuit.

When the battery has been assembled, it’s basic function depends on negative and positive electrodes. These electrodes must be made of unlike materials. If they aren’t, the cell won’t be able to conduct an electric current. Negative electrodes provide electrons to the external circuit, which is sometimes known as load, during discharge. Positive electrodes receive electrons from the external circuit during discharge. In a fully charged forklift battery, the negative electrode is made of sponge lead, while the positive electrode is made up of lead dioxide. In order to keep the positive and negative electrodes isolated, a separator needs to be used. Separators can be made using different materials, generally plastic or glass that is permeable. It’s important to keep the electrodes apart because if they come into contact, the cell will short-circuit.

Electrodes aren’t the only important elements in battery function, the electrolyte mentioned above plays a critical role. Electrolyte is a substance that is able to conduct electricity once it’s dissolved in water. In lead acid batteries, the electrolyte is diluted sulfuric acid (usually 37.52% sulfuric acid and 62.48% water). The electrolyte completes the internal circuit in a battery. It’s able to do this by dispensing ions to both the positive and negative electrodes. Temperature is another important element affecting lead acid batteries. Heat can cause evaporation, so the forklift batteries need to be checked and watered when needed and in the winter batteries can freeze.

"When a battery is fully charged the electrolyte will not freeze until the temperature drops to approximately -92°F; however, if there's only a 40% state of charge the electrolyte will freeze when the temperature drops to approximately -16°F. There's some good news though, battery operating time will increase somewhat for temperatures above 77°F. And the flip side being that the operating time will be decreased, significantly in some cases, for operating temperatures below 77°F."

Source: DCPS Blog "Can My Batteries Freeze"

When you’re charging your forklift battery, it should be charged at the 20C rate. This means that the battery is being charged at 20% of the total Ah (amperehour) capacity of the battery when using conventional charging. Alternative charging can go as high as 50C, but will adversely effect the longevity of the battery. The 8-8-8 Rule helps explain forklift battery charging. Learn more about DC Power Solutions forklift battery preventative maintenance or contact us if you need help with your batteries.